Non Ferrous Foundry Plaster

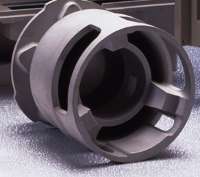

Hoben International are the worlds leading manufacturer of Foundry Plaster which is a gypsum bonded investment formulated for casting Non Ferrous Metals. Foundry Plaster is used in the Rubber Plaster Mould (RPM) process which utilises a reclaimable pattern of silicone rubber.

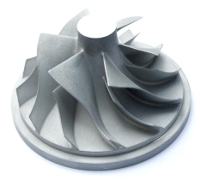

Hoben Foundry Plaster has been used for many years by leading foundries specialising in the high volume production of turbocharger compressor wheels. Foundry Plaster is also used for the manufacture of lower volume castings and in the rapid prototyping sector.

|

When and why to use Hoben Foundry Plaster:

For full product details please refer to the product data sheet. |

Downloads

Unable to open PDF documents? Please download Adobe Reader for free from Adobe's website. |